20 Years of VIVA Railings | 2005 – 2025 Learn More

Introducing CeraShield: The Future of Coating Technology

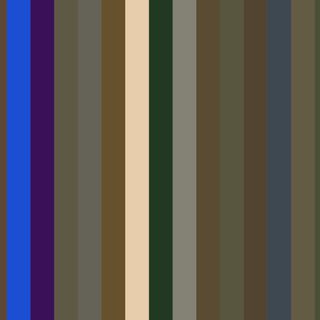

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

- CS-102 GRAPHITE BLACK

- CS-138 JET BLACK

- CS-7300 BLACK VELVET

- CS-112 COBALT

- CS-186 PISTON COAT (AIR CURE)

- CS-129 STAINLESS

- CS-124 SATIN NICKEL

- CS-219 GUN METAL GREY

- CS-226 PATRIOT BROWN

- CS-187 TRANSFER GREY

- CS-239 SNIPER GREY

- CS-231 MAGPUL FOLIAGE GREEN

- CS-232 MAGPUL O.D. GREEN

- CS-241 O.D. GREEN

- CS-244 MIL SPECS O.D. GREEN

- CS-215 HIGHLAND GREEN

- CS-240 COYOTE TAN

- CS-7900 GLACIER TITANIUM

- CS-267 MAGPUL FDE

- CS-30118 FS FIELD DRAB

- CS-148 BURNT BRONZE

- CS-190 20150 COYOTE

- CS-7800 GLACIER GOLD

- CS-211 DESERT SAND

- CS-143 STOPLIGHT RED

- CS-163 LOLLYPOP PURPLE

- CS-158 BLUE FLAME

Advanced Technology Backed by CERAKOTE

VIVA Railings leverages the advanced technology of CERAKOTE, a world-renowned coating technology celebrated for its superior durability, corrosion resistance, and aesthetic versatility. By integrating CeraShield's proven methods, VIVA Railings ensures that our coating delivers unmatched performance and aesthetic excellence. Visit Cerakote for more information.

A New Standard in Finishing

Explore the key features and extensive color options of CeraShield™, designed for exceptional performance and aesthetic appeal in any environment.

Unmatched Color and Application Flexibility

CeraShield by VIVA Railings redefines the possibilities of finish applications with its versatility across materials. Offering over 40 vibrant and unique color options, CeraShield can be applied to stainless steel, aluminum and steel. This universal coating serves as an excellent alternative to anodizing, which is limited by the materials it can coat and a narrow color palette due to the chemical nature of the process.

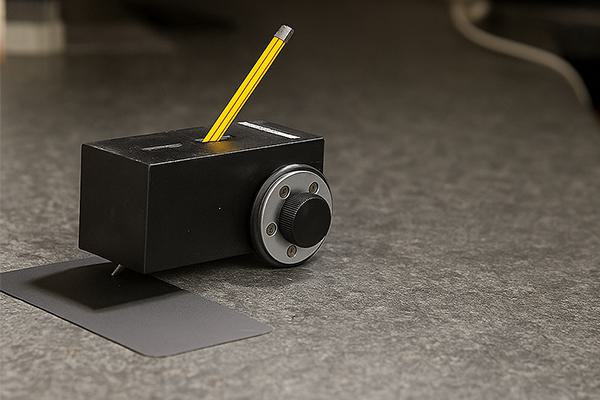

Pencil Hardness Test - Used to determine the hardness of a coating by evaluating its resistance to scratching using pencils of varying hardness. The test involves pressing pencils with different hardness grades against the coating surface and observing the hardest pencil that does not leave a mark.

Cerasheld: 7H - 9H Standard Powder Coat Color: 2H - 6H

Flaking Test

Maximum temperatures that a particular coating can withstand before it starts flaking.

Cerashield: 800°F - 1200°F Standard Powder Coat Color: 500°F

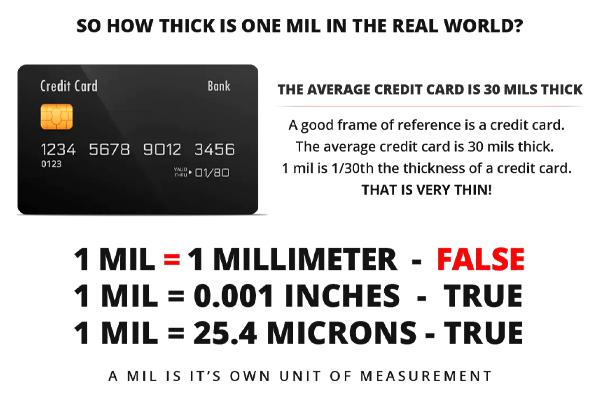

Mil Thickness

Thickness of the coating. Average powder coating thickness is about 2mil to 6mil. CeraShield colors have met ASTM standards for Salt Spray tests, Impact Resistance test, Pencil Hardness tests all with 1 mil thickness.

Cerashield: 1 MIL Standard Powder Coat Color: 4 MIL

The Preferred Choice for Professionals

Architects, General contractors and industry professionals that care for reliability, consistency, extensive color selection, and faster turnaround times, will love our new CeraShield finish

Explore the advantages of CeraShield for your next project.

Superior Color Consistency

CeraShield stands out with its exceptional color consistency. Every CERAKOTE color adheres to a strict standard of Delta E ≤1, ensuring minimal perceptible variance where the human eye typically detects differences at a Delta E of 2 or more. This level of consistency makes CeraShield an ideal choice for high-volume projects requiring uniform finishes, unlike anodizing which can exhibit significant color variations from batch to batch.

Enhanced Performance on Aluminum Alloys

Unlike anodizing, which can compromise the integrity of aluminum alloys by inducing brittleness and tensile residual stress, CeraShield maintains the metal’s fatigue properties. This characteristic preserves the longevity and durability of aluminum components, allowing them to retain their structural integrity over time.

Environmental Responsibility

CeraShield is a leader in eco-friendly coating solutions. Free from heavy metals and compliant with VOC regulations in all 50 states, it meets stringent REACH, ROHS, and Proposition 65 standards. In contrast, traditional anodizing processes involve the use of hexavalent chromium, a known carcinogen with increasingly restricted use under environmental regulations.

Corrosion tests have been performed as per ASTM B117 standards (salt spray chamber) where the product lasted for 2034 hours, exceeding the requirements of 1000 hours. CeraShield by CERAKOTE Corrosion Test Video

Shown here are the standard colors available.*

DISCLAIMER

*Please note that the digital swatches of our CeraShield may not accurately represent the actual real-life samples. Factors such as monitor settings, lighting conditions, and individual perception can affect the colors you see on your screen. We suggest using the swatches as a general reference for color, shade, and hue, rather than expecting an exact match. For the most precise color selection, we recommend requesting physical samples or visiting our office in Lewisville, TX to evaluate the powder coat colors in person.

Please note that while we offer a diverse range of standard CeraShield colors to complement our products, any selections outside of these standard options may incur additional costs. We encourage you to consult with our specialists to explore all available options and make the best decision for your project needs.