By Connie Quimby, Design & Specification (Nationwide) at VIVA Railings

20 Years of VIVA Railings | 2005 – 2025 Learn More

20 Years of VIVA Railings | 2005 – 2025 Learn More

By Connie Quimby, Design & Specification (Nationwide) at VIVA Railings

In architectural design, railings often sit at the intersection of form and function — highly visible, heavily regulated, and critically important to safety. Yet across thousands of project plans reviewed by the team at VIVA Railings, common mistakes continue to surface in railing specifications, even on large, well-resourced projects.

These oversights are rarely due to negligence — more often, they stem from outdated assumptions, fast-tracked deadlines, or coordination gaps between disciplines. As VIVA’s national point of contact for design and specification, I’ve gathered the most frequent missteps architects and general contractors make when specifying railings — and more importantly, how to avoid them.

Whether you’re in early-stage design or working through VE options, this guide will help you spec smarter, reduce RFIs, and deliver better outcomes.

Assuming IBC compliance is enough — and overlooking local or AHJ-specific code amendments that affect railing height, load, or opening limitations.

Always verify local code overlays and special jurisdiction requirements (e.g., hospitals, schools, or seismic zones). While VIVA’s systems are engineered for IBC compliance, we often work with clients to modify dimensions or infill types to meet site-specific needs. Early coordination with local code officials can prevent late-stage redesigns.

Specifying top mount or fascia mount without confirming structural backing, edge clearance, or waterproofing compatibility.

Engage with structural and waterproofing consultants early to confirm slab edge details. VIVA offers detailed CAD files and section views for every mounting condition — use these during schematic or DD phase to align with reality. When in doubt, send us your section and we’ll recommend compatible systems.

Choosing infill (glass, cable, panel) based solely on aesthetics — without considering use case, fall risk, or IBC climbability rules.

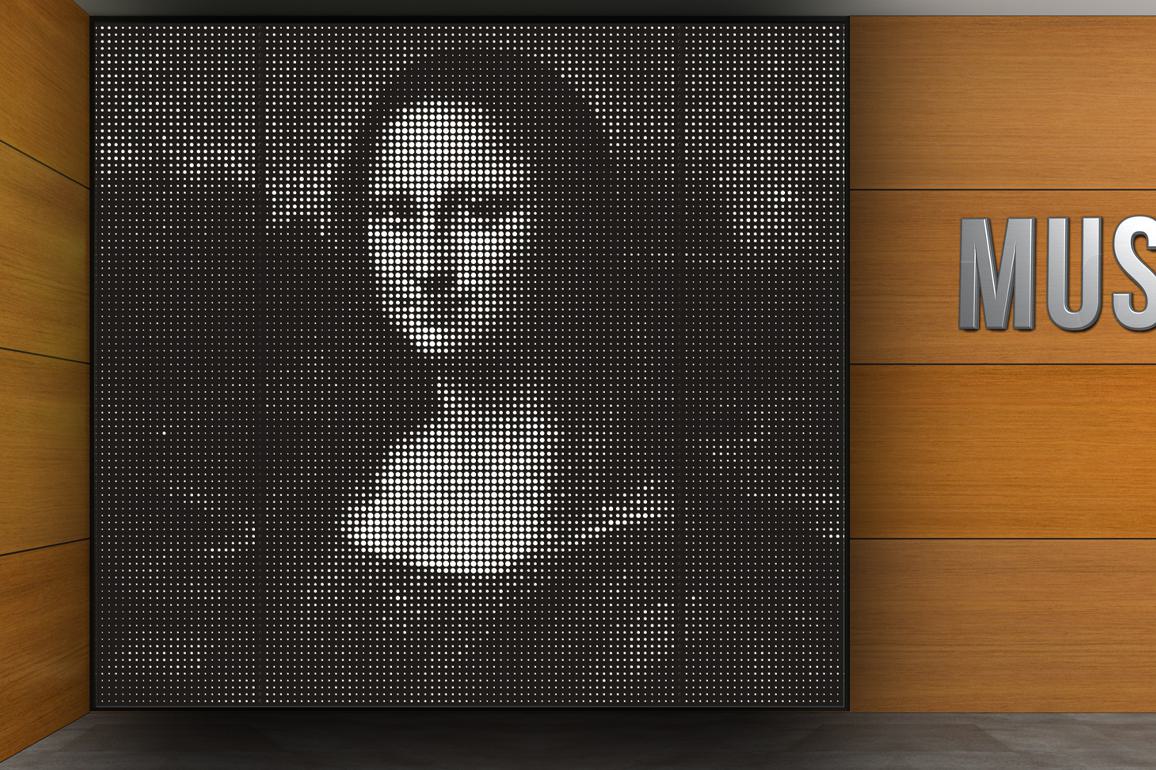

Match infill to function. For example, cable railing may be great for residential balconies, but not for school staircases. Laser-cut panels like FOLD™ and PERF™ offer anti-climb and code-friendly solutions with design flexibility. VIVA can recommend infills that meet safety requirements and elevate your design.

Assuming all railing posts can be spaced evenly without factoring in allowable deflection or span limits — especially on glass or stainless systems.

Deflection isn’t just an engineering issue — it affects comfort and perceived safety. Always consult system-specific span tables and deflection limits. VIVA’s glass railing systems (like SHOE™ and CIRCA™) are tested to perform under live loading but require precise spacing to avoid flex or failure.

Leaving finishes as “match existing” or omitting details on lighting integration — leading to RFI delays or costly rework.

Be precise. Specify finish codes (e.g., brushed SS #4, powder coat RAL) and confirm compatibility with exterior or coastal conditions. For lighted systems like iRAIL™, call out voltage, fixture type, and whether it needs to integrate with building power. VIVA offers pre-engineered lighted rail solutions with full photometric data and wiring plans.

Railings aren’t just a product — they’re a performance system. Done well, they elevate both safety and aesthetics. Done poorly, they invite costly fixes.

At VIVA, our goal is to make railing design as seamless and spec-friendly as possible. With resources like CAD files, engineered drawings, BIM models, and direct design support — we’re here to help you get it right, from concept to install.