20 Years of VIVA Railings | 2005 – 2025 Learn More

In House Fabrication- A Hallmark of VIVA’s Excellence!

In our series of short video stories, this month we highlight the production process of our metal panel railing system and our architectural metal panels.

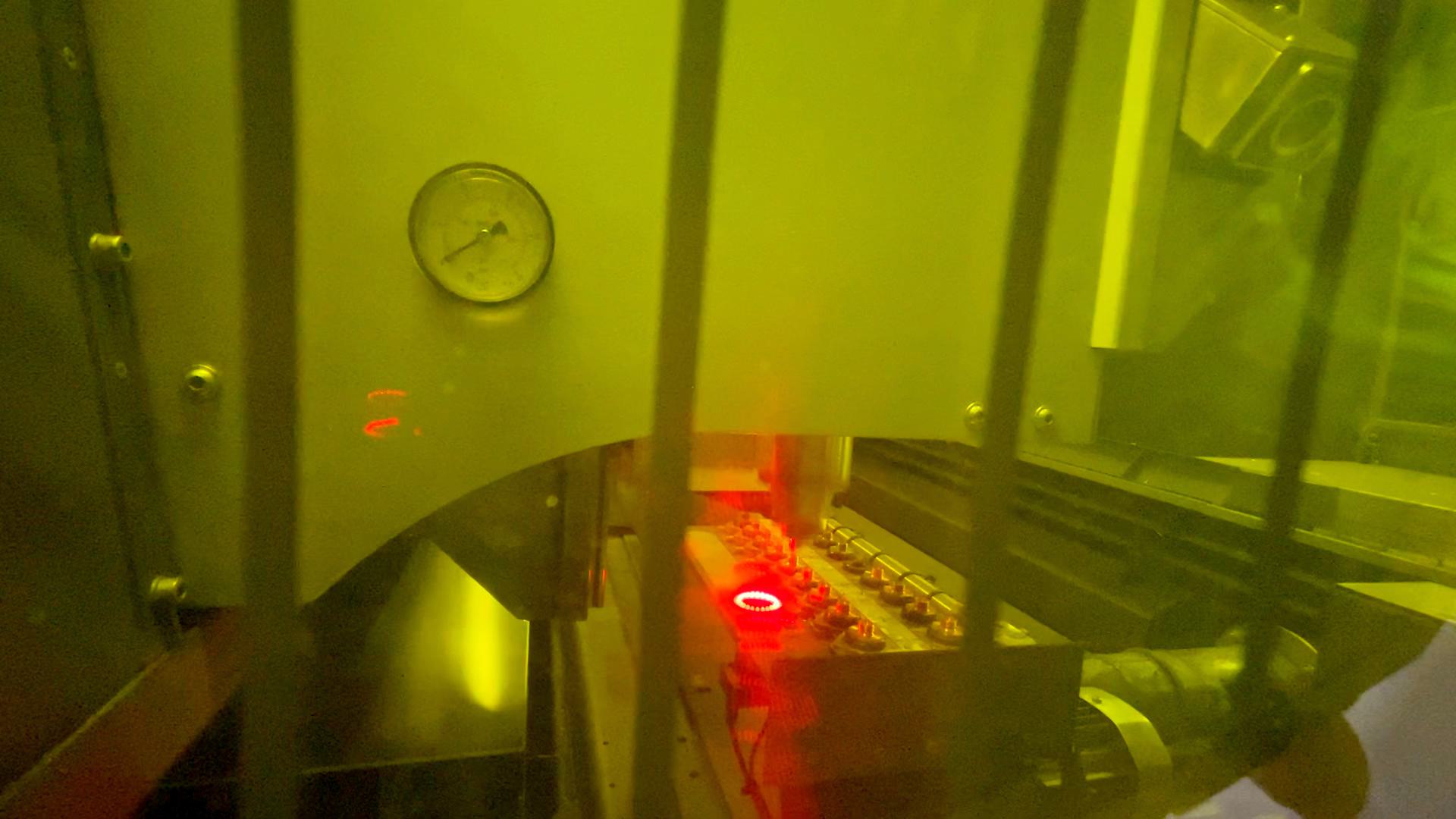

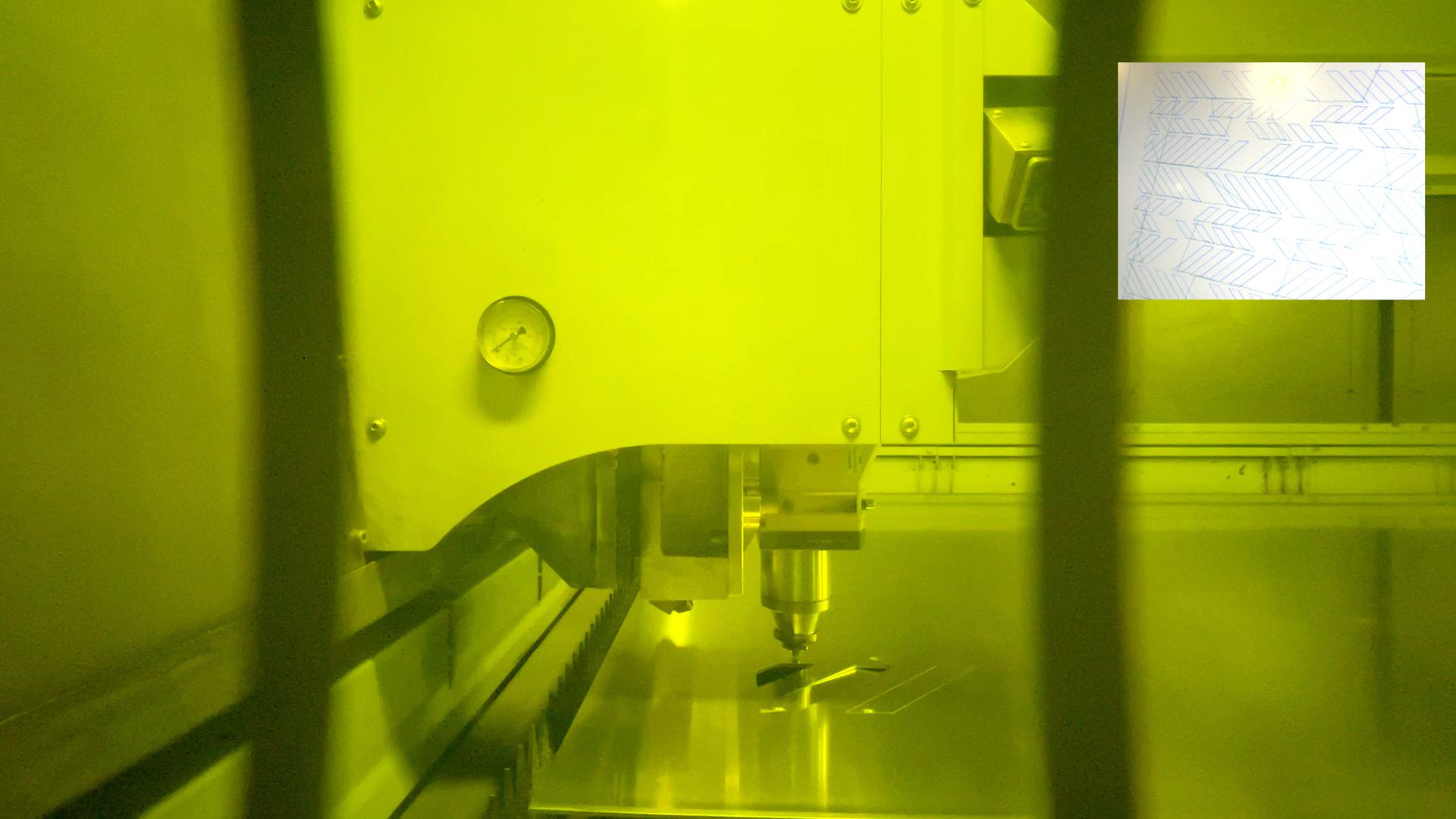

Our state-of-the-art Fiber Laser Cutting Machine does a precise job of cutting panels from stainless steel or aluminum sheets.

To fabricate our STRUC and FOLD Panel Railings Systems and our extended line of Architectural Metal Panel systems we use our state-of-the-art fiber laser cutting machine.

Let's see how it's done at our in-house workshop in Lewisville, Texas.

Our powerful and compact robot picks up panels with ease and lays them on the laser bed with precision.

Our laser machine operator completes review of the job and when all parameters are in place, the cutting sequence is initiated.

The laser bed and the stainless steel or aluminum panels then travels to the cutting area.

The laser head checks the material and pattern and picks up the most suitable cutting tool for the job.

The laser delivers high speed and precision cutting of any of our standard patterns or custom patterns.

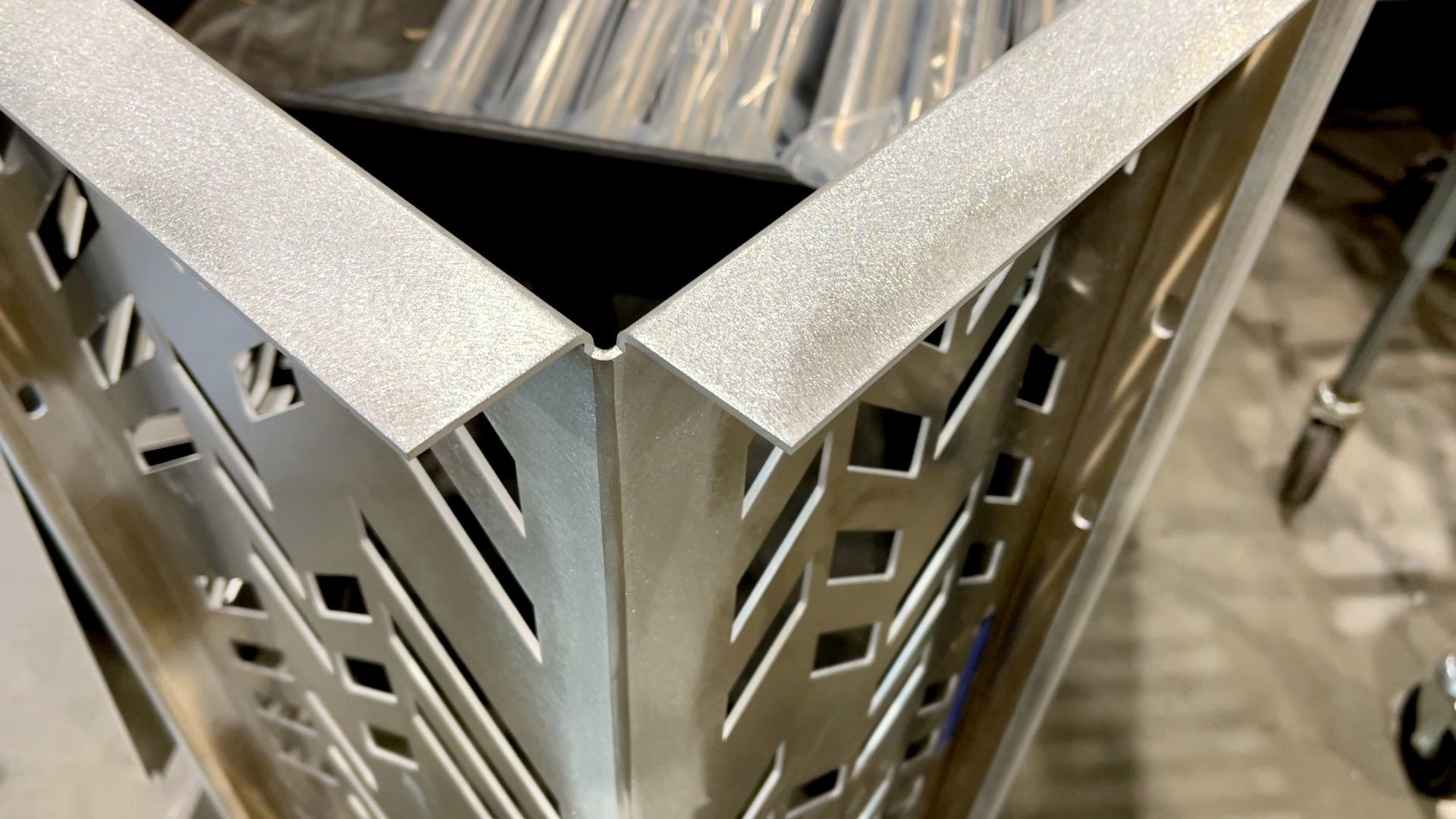

Once the cutting is complete, the panels are sent to our high capacity bending machines.

Once the bending is complete, the panels are sent to the finishing area of the our workshop where our skilled workers complete the jitterbug finishing that removes burr and bed marks.

Now these panels are ready to be sent over for powder coating.

Watch our short video to learn more about our in-house fabrication process for our laser cut metal panel railing systems and architectural metal panels.

We love to have architects, general contractors and owners to our headquarters in Lewisville, TX.

You can visit our Design Experience Center and also our workshop and warehouse.

Come see for yourself how we design, engineer and fabricate complete railing solutions for your expertly designed spaces.