The recent years in the commercial construction industry have been chaotic, to say the least. Operational disruptions caused by the pandemic have thrown a wrench into the manufacturing of essential materials, as well as their transportation. This strain has been further exacerbated by increased demand for new builds, which has only driven up material prices all the more. Such a complex combination of factors has posed an incredible challenge for contractors who are trying to keep projects on schedule, on budget, and still true to the quality of their original design.

In this post, we discuss how supply chain issues are threatening commercial projects in detail, and explore strategies for minimizing or eliminating problems altogether. We place a special focus on sourcing an architectural railing system – an installation that can easily offset project progress if the chosen supplier isn’t reliable and efficient.

How Supply Chain Issues Impact Commercial Projects

Price hikes, material shortages, and shipment delays have affected global, national, and even local supply chains. Such widespread stress on the market has derailed countless commercial projects. Many have had their budgets blown by sky-high material costs, pushing stakeholders to put work on pause until market conditions improve. Others have suffered expensive delays due to unstable shipping schedules and transportation’s own ever-inflating prices.

This impact on projects already underway has obviously been disastrous for contractors, but these supply chain obstacles also affect their ability to win new bids. Many contractors are being priced out of the competition because they are unable to offer the low-cost quotes developers are looking for. Some, thanks to economic stress, no longer even have the labor force required to take on projects they would normally pursue.

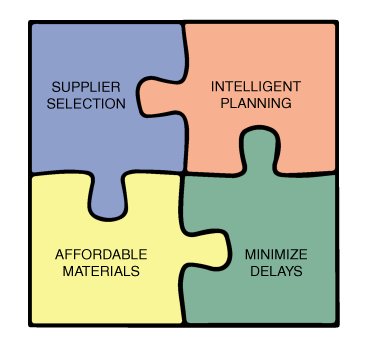

Solutions That Address These Issues

The burdens described above have made it absolutely imperative for contractors to somehow minimize delays and source their materials more affordably. When it comes to securing commercial railings, satisfying both of these requirements calls for intelligent planning and supplier selection. We examine three highly effective methods for this, below.

Seek Companies with Vertical Integration

When multiple manufacturers are relied upon to compose a single product, supply chain vulnerability is high. In the commercial railings industry, it is, unfortunately, quite common for suppliers to source railing components from other companies, selling a collection of disparate parts as a unified, branded product. But a hiccup in the operations of just one of those component producers can completely tank a supplier’s ability to deliver their railings.

To avoid this risk, we recommend only partnering with railing suppliers that have vertically integrated all of the manufacturing entailed in their product’s development. With a supplier that produces all of their railing components in-house, there will be no worry over whether or not sourcing troubles will arise from third-party contributors.

Look for Suppliers with Enhanced Sourcing Capabilities

The sheer logistics of getting materials to construction sites has been especially challenging right now. It’s only exacerbated by the fact that many suppliers are having difficulty sourcing the materials needed for their own manufacturing and product packages.

Suppliers with these limitations simply don’t have the capacity to offer quick fulfillment to contractors at this time. That’s why it has become critical to choose one that has the ability to source both locally and internationally, keeping up with customer demands for architectural railing systems at a time when there are serious shortages. The ideal supplier should also have domestic manufacturing, eliminating the worry that overseas shipping disruptions will cause unexpected delivery delays.

Make a Preference for Prefabrication

With all of the delays afflicting commercial projects at the moment, it is paramount that contractors cut down the time spent not just waiting for railings to arrive, but also for them to be installed. Selecting prefabricated railing products can significantly reduce the time needed to check railings off the list of materials that still need to be installed. Prefabricated railings are already assembled and ready to deploy upon arrival at the construction site, meaning that an entire portion of the outstanding work has been eliminated from the project.

Even greater streamlining can be achieved by choosing a supplier that provides its own installation service. This saves on the cost and insecurity of hiring inexperienced labor that isn’t familiar with the railing products. Whereas third-party installers may require extra labor hours to get the job done, the supplier’s team will be able to complete the work quickly. There’s also a certainty that the installation will be performed correctly, resulting in one less worry for an already complicated project.

Finding a Dependable Commercial Railing Contractor

Identifying a railing supplier that offers all of these supply chain protections is particularly hard in a market where manufacturers are trying to lower their own costs as much as possible. Contractors need a partner that has the stability, network, and integrity to meet the standards that will keep their projects going strong.

VIVA Railings has proudly made each of these qualities an integral part of its business, allowing for consistent fulfillment contractors can always trust in. Our distribution centers are spread far and wide, enabling optimal service for projects in every state. Sourcing is adapted to fluctuating demands, switching between local and international as needed when shortages or logistical issues arise. This extensive logistical experience and the comprehensive network have empowered us to streamline projects nationwide.

With VIVA, the full spectrum of service is fulfilled, from design and engineering to fabrication and installation. Manufacturing disruptions are a bygone worry, thanks to the fully-internalized production of all railing components. The in-house design facilitates entirely custom applications. And with railings delivered completely prefabricated and ready to install by our experts, we’re able to have a project’s railing solution fully closed-out in the fastest time possible.

To learn more about how VIVA safeguards contractors and their commercial projects, contact us today. We’re happy to go over our catalog of products to discuss specific project needs, and further demonstrate how we’ve achieved supply chain resilience.